Beyond Recycling: How Circular Manufacturing Creates Lasting Competitive Advantage

Strategic Insights From Two Manufacturers On Transforming Sustainability Into Profitability

Circularity—the idea that a company can produce a product, sell it, have it used by the buyer, then reclaim it at end-of-life to be remade into a new product—has been a focus of sustainability discussions for years now.

However, while a lot of companies talk about circular design, I came across two recent examples of two very different manufacturers doing it right.

One is a 150-year-old family business; the other is one of the largest organizations on Earth.

Both are doing it for a core business reason: Circularity can be very profitable. Not only that, it can create a significant competitive advantage.

Here’s how.

Let’s Start Big

Toyota Motor Corporation — yes *that* Toyota—is a behemoth. With dozens factories across five continents, hundreds of models across four primary brands and 10.8 million cars manufactured annually (that’s 20 vehicles a minute!), Toyota is one of the largest manufacturing companies in history.

It’s also one of the most innovative. The company that created the manufacturing concept of kanban is now going all-in on circularity—for automobiles.

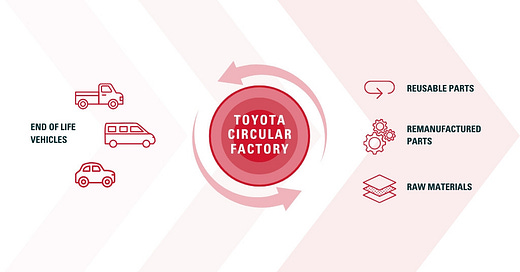

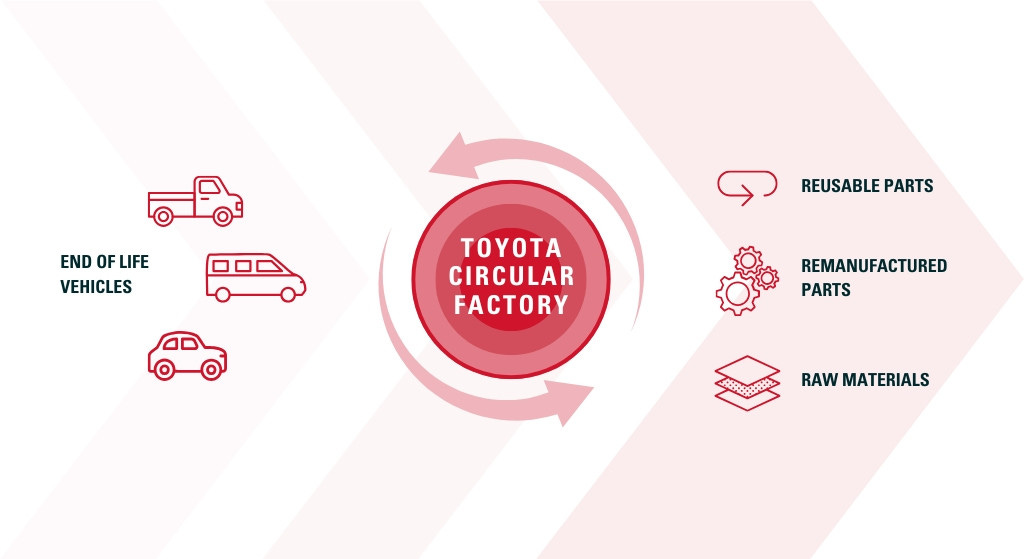

Toyota just launched a first-of-it’s-kind “Circular Factory” in Europe. The goal is to systematically bring the concepts of recycling, repurposing and remanufacturing to cars at the end of their lives.

The vision is simple and exciting: Take old cars off the road and break them back down to parts. Parts that can be refurbished and reused get reintroduced to retailers and parts distributors as certified reused parts. Other commodity parts, such as wheels, get remanufactured, repurposed into new uses or recycled, depending on their condition.

Raw materials in the car, such as copper or aluminum, get recycled—reducing Toyota’s reliance on virgin materials.

We initially anticipate recycling around 10,000 vehicles a year in our UK facility, which will give new life to 120,000 parts, recover 300 tonnes of high purity plastic and 8,200 tonnes of steel - amongst other materials. As a next step for the Toyota Circular Factory concept, we plan to roll out similar operations across Europe. And we’re not stopping at our own facilities - we are eager to collaborate with other organisations who share our passion of circularity and commitment to carbon neutrality

Leon van der Merwe, Vice President of Circular Economy at Toyota Motor Europe

The initiative’s goal is to reduce the environmental impact of car manufacturing and lower Toyota’s overall carbon footprint—a fantastic goal (Toyota has a goal of being carbon neutral in its European owned facilities by 2030).

Introducing circularity now also gets the company ahead of potential recycle/reuse regulations in the European Union.

Don’t miss the business impact though: Toyota is also doing this because it’s cheaper to refurbish and reuse parts.

Value Beneath Your Feet

Circularity isn’t just for mega-corporations though. An emerging leader in circularity is Ecore International, a 150-year-old family business headquartered in Lancaster PA that makes rubberized flooring—also known as gym floors.

Think gym floors and rubberized flooring is a surprising place to find sustainability innovation? Me too, until I spoke to Shweta Srikanth, the company’s Chief Circularity Officer.

She explained that the circularity advantage that Ecore has is that rubber, as a material, is a versatile material that can be recycled multiple times—and the company has realized they can turn this into a competitive advantage over their competitors.

In their evolving model, Ecore plans to take back their product once it’s reached the end of its useful life. This product is then sorted, recycled, and fashioned into new flooring—which often can be sold to the same end market they reclaimed the old flooring from.

Through their end-of-life management, Ecore plans to develop long-term relationships with its customers, giving them the best on-going flooring experience possible. It also strenghtens the company’s own margins.

Because not only is reusing and recycling their old products a values decision for the company—its sustainability work goes back decades—it’s also more profitable than creating flooring from new rubber.

In addition to lower costs, there are two strategic bonuses:

First, recycling their own product locks in a source of materials that doesn’t fluctuate like the cost of virgin rubber does. Cost stability enables better long-term planning and forecasting, and it frees up capital that might have been set aside to cover unanticipated price spikes.

Second, by dealing with the end-of-life of the floor for their customers, they’re already in discussions with their customers before any other supplier. Customers aren’t locked into Ecore products, per se, but the company does have the inside track on the next sale.

Critically, Srikanth’s charge is to demonstrate that this business can be more profitable for eCore than traditional production models.

Just like Toyota (or Patagonia’s Worn Wear Program), this initiative is an extension of the company’s leadership’s values—Ecore already reclaims 430 million pounds of rubber annually, and the company’s sustainability roots go back to the days when it was manufacturing cork products.

But its circularity work wouldn’t be something the company could pursue long-term if it didn’t make business sense. Businesses have to be profitable and strong to stay in business—circularity is a competitive advantage for Ecore.

(How to) Run In Circles

If you manufacture a product, should you explore circular manufacturing? Yes. But your team needs to approach the opportunity strategically:

a/ Focus On (Long-term) Profitability.

For circular manufacturing to take hold in your company, it needs to be more profitable than your current manufacturing process. This doesn’t need to happen on day one—there’s a learning curve for any change, and changing to a new manufacturing process is a major one—but you need to have a path to profitability.

Why?

Because, like with any sustainable innovation in your business, if the business rationale for the change isn't sound, it won’t last.

b/ Circularity Requires Ingenuity.

You’re attempting something new in your organization—that, by definition, requires some level of ingenuity.

What makes circularity so exciting, however, is that it opens the opportunity to innovate on all aspects of your product experience. You can rethink product design, manufacturing processes, supply chains—and even the business model itself. (Rental models, anyone?)

All of these rethought elements can work together to create a stronger business for your organization—and one that your competitors will have difficulty replicating. This competitive advantage will strengthen your business for years to come.

c/ Product Leads the Way

At its core, a circular system revolves around the product—you’re rethinking the product experience from cradle to grave to cradle again. Because the product is central to the process, this is one area of sustainability where experienced product managers can really shine.

A great product manager knows how to balance stakeholder needs, rethinking products and processes, work across functional lines, manage a P&L and bring a new product to market. If you’re exploring circularity and considering bringing circular concepts into your business, having product management experience on your team will be critical to success.

Do you have experience running a circular business, is your team exploring the space, or do you know of other inspirational stories I’d love to know about? Drop me a note—I’d love to hear from you!